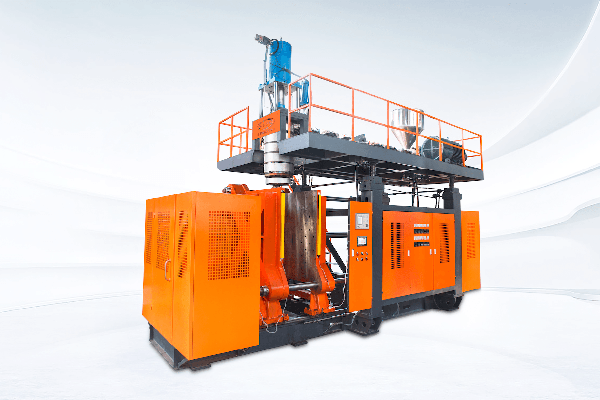

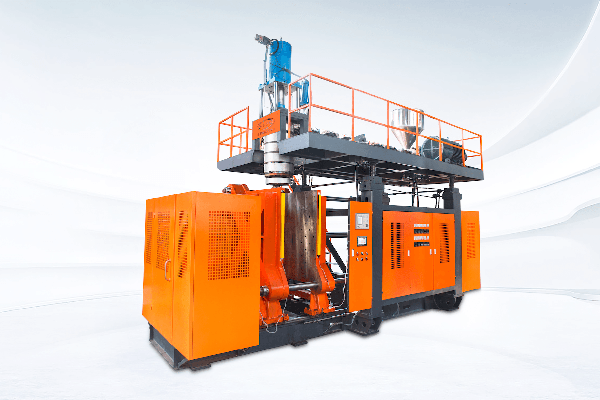

HT-160 Double Sided Tray Blow Molding Machine: This machine is a hydraulic full-automatic blow molding machine with accumulator type, fully adopts German technology, and can blow thermoplastics such as PE, PP, AS and other thermoplastics with a capacity from 100 liters to 3000 liters hollow container. This machine is fully automatic production, high energy saving, low noise, fast speed, high efficiency, safe and reliable, widely used in chemical, petroleum, pharmaceutical, daily chemical, food, lighting, tools, automobiles, motorcycles, shoes, toys and other fields , used to blow plastic barrels, chemical barrels, auto parts (water tank, fuel tank, air conditioning outlet duct, car rear wing), toys (wheels, hollow motorcycles, basketball racks, children's castles), tool bags, dust collector pipes, sports Venues and bus seats, etc. Safe transfer, commissioning, training, complete quality assurance, and full-service service make you feel at ease when purchasing and using them.

1. Control system: The operation panel uses a 5.7-inch Chinese human-machine interface touch screen, and all actions, parameter setting, monitoring, product counting, wall thickness control and other visual operations. Equipment failure self-judgment display, easy to operate. The PLC programmable controller imported from Japan's Mitsubishi has the function of storing and mobilizing process parameters, fast response, accurate positioning, and high stability of the system during operation.

2. Hydraulic system: all imported hydraulic valves, seals, electro-hydraulic proportional control. It has the characteristics of stability and reliability, accurate action, long service life and fast response.

3. Extrusion system: It adopts a hard-tooth surface reduction gear box and a Mitsubishi inverter imported from Japan, which has the characteristics of screw frequency conversion speed regulation, low noise, strong power, stable rotation speed, long service life and energy saving; mixing screw, raw material adaptability Wide range, better plasticizing quality, heating barrel and aluminum alloy heater, high efficiency and energy saving.

4. Die head system: The center injection and storage cylinder type die head is adopted, and the horizontal bar is injected with high stability. The "first-in first-out" storage head has a reasonable and reliable structure.

5. Mold opening and closing system: pneumatic single-cylinder slide rail, fast and stable, four-platen, high-precision linear guide rail, hydraulic double-cylinder two-way mold opening and closing.

6. Model girdle control system: Japanese MOOG and domestic 10 to 100 point wall thickness control system are optional

7. Air blowing system: Standard down blowing, side blowing and up blowing are optional.

8. Die cutter: Standard pneumatic die cutter, fast standard.

9. Safety system: equipped with mold clamping protection device and light curtain sensor to ensure the safety of equipment and operators.

10. Electrical components: all use international general high-tech products.

| Model | HT-160 | ||

| Basic specifications | Applicable materials | PE... | |

| Product capacity | 3000L | ||

| Number of Dies | 1 | ||

| Number of stations | 1 | ||

| Dimensions | 10.5M*7.0M*7.5M | ||

| Machine weight | 45 tons | ||

| Extrusion system | Screw diameter | 135mm*2 | |

| Screw aspect ratio | 32:1 L/D | ||

| Plasticizing capacity | 600kg/h | ||

| Number of screw heating sections | 7sections | ||

| Screw heating power | 48KW | ||

| Extrusion motor power | 132KW*2 | ||

| Die head | Storage tank volume | 120L | |

| The maximum diameter of the extrusion port | 1300mm | ||

| Die head heating section number | 8 section | ||

| Die heating power | 60KW | ||

| Mould opening and closing system | Template spacing | 1000-3400mm | |

| Maximum mold size | 1800*2500mm | ||

| Mold thickness | 1050-1300mm | ||

| Clamping force | 2200KN | ||

| Power | Power supply | 220~380V,3-phase50~60HZ | |

| Host drive power | 30Kw | ||

| Maximum total power | 300Kw | ||

| Screw fan power | 1.2Kw | ||

| Average energy consumption | 135Kw | ||

| Air source pressure | 0.7Mpa | ||

| Air source displacement | 0.9m3/min | ||

| Water source | Cooling Tower | ||

Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.